Predictive Maintenance (PdM) and Condition Monitoring (CM) Services

PdM Services Overview

ASI provides expertise and support in the development, application, installation, and collection of highly successful Predictive Maintenance (PdM) and Condition Monitoring (CM) systems and programs. Our staff includes

ASI provides cost-effective comprehensive PdM services including:

PdM Program Development & Planning

Condition Monitoring System Design & Installation

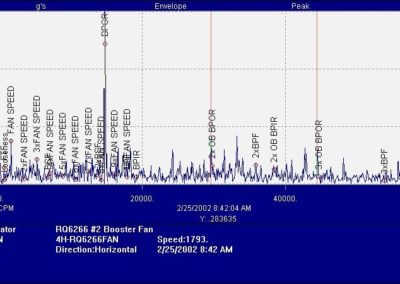

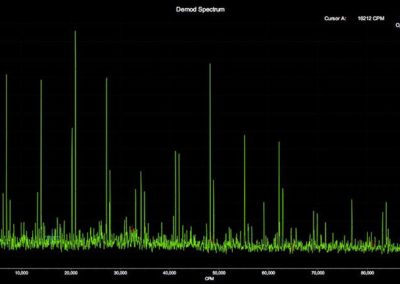

Vibration Analysis

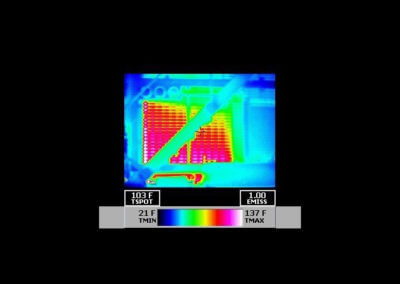

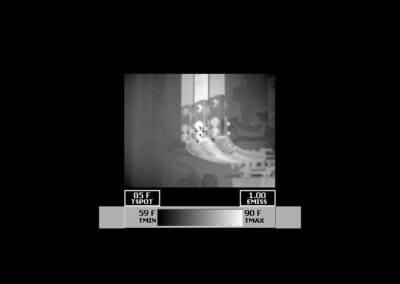

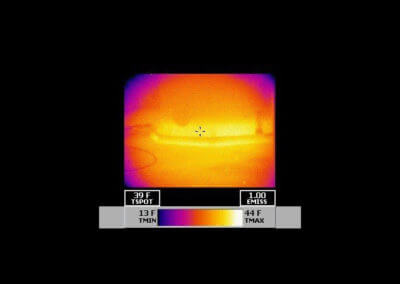

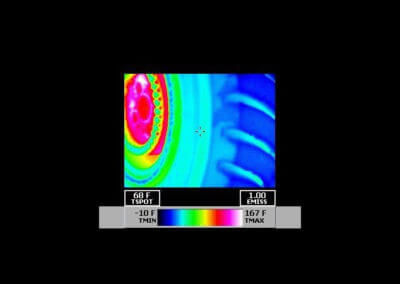

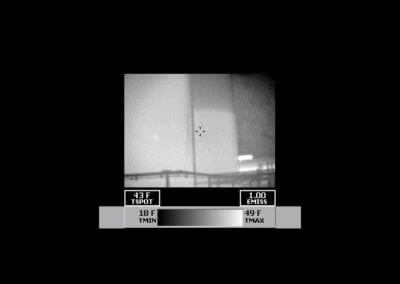

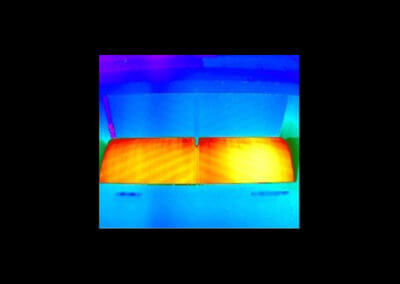

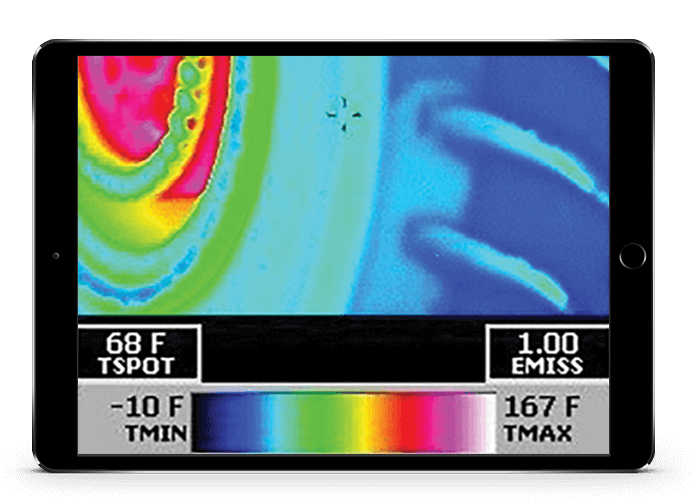

Thermal Imaging (Thermography)

Ultrasonic Inspection

Oil Analysis

Non-Destructive Testing (NDT)

Motor Circuit Analysis

Predictive Algorithm Development

When applied properly, PdM is one component of an optimized support program that should be integrated and coordinated with the entire asset management program. Predictive maintenance, when applied to failure modes that have been evaluated through RCM analysis or maintenance engineering processes, provides a real-time indication of equipment condition allowing maintainers ample time to react prior to function loss or catastrophic failure. The Department of Energy’s Operations and Maintenance Best Practice, Release 3.0, estimates that a predictive maintenance program, initiated from a totally reactive program, could provide upwards of 35% to 40% reduction in downtime. Predictive maintenance programs allow for the full benefit of the planning and scheduling function to be realized.

Features

PdM technologies provide near real-time, accurate, and reliable equipment condition information for effective decision making.

Our analytical-based approach ensures that the right technology is applied to the appropriate failure modes on the right equipment

We provide a business case for the implementation of specific PdM technologies

We offer route based, baseline, and troubleshooting evaluations and both installed permanent and portable solutions

Our staff includes ASNT/ISO certified PdM technicians

Our solutions include fault tracking and trending capabilities

We utilize the latest technologies and equipment

We integrate PdM solutions into existing maintenance management systems

Benefits

Reduced maintenance cost and asset downtime

Minimize risk of downtime in critical assets

Maximize asset useful life

Global visibility of asset health and condition

Improved ability to plan and optimize the utilization of resources

Case Studies

1. US Army Medical Facility

We developed and implemented a comprehensive RCM and CBM based maintenance program that included assessment of facility equipment for PM Optimization, Criticality and Risk Assessment, PdM opportunities, analysis of appropriate technologies for specific equipment and failures, and comprehensive development, installation, and implementation of a Predictive Maintenance program. The resulting program included vibration analysis, oil analysis, infrared imaging, ultrasonic emission testing and motor circuit evaluation for critical equipment. Implementation of this program achieved a marked reduction of maintenance Man-Hrs by 39%

2. Major US Airline Data Center

We implemented an intensive and comprehensive maintenance program for a large data center that included complete equipment evaluation and analysis that resulted in an RCM justified preventive maintenance program utilizing the latest in predictive maintenance technologies and evaluation. This analysis of a new green field project successfully developed an optimized PM plan for critical electrical equipment that included complete Maintenance Task Analysis, PdM Plan and Lock Out-Tag Out procedures. An expected reduction of approximately $160,000.00 should be realized from original PM program costs with full implementation of the optimized Preventive and Predictive Maintenance program.

3. F-35 Prognostics and Diagnostics

We are part of the development team for a fully comprehensive condition based and prognostic health diagnostic and mitigation program for the F-35 Program Office. These efforts include the use of data supplied by both onboard and adjunct sensors, the latest data collection techniques, and algorithm development to provide prioritized, probabilistic and predictive information to the management team. In addition, Business Case Analyses (BCA) are conducted to determine the viability and benefit of proposed improvements.

Additional Predictive programs have been developed for heavy industry including manufacturing and precision machinery, mining, mineral processing facilities, and facilities infrastructure.

Contact Us

Engage an ASI PdM expert with your maintenance or management team and leverage the benefits and value of predictive maintenance utilizing the latest in the predictive technological advancements and techniques.

Corporate Headquarters

440 Viking Drive, Suite 230

Virginia Beach, VA 23452

Corporate Office

6255 Lake Gray Blvd., Suite 4

Jacksonville, FL 32244

USA Offices

Crystal City, VA

Havelock, NC

Oklahoma City, OK

Patuxent River, MD

San Diego, CA

Get in Touch

904-637-2020

Follow Us

Email Us

"*" indicates required fields