AIMS: Your All-in-One Aviation Maintenance Solution—Because Mission Readiness Can’t Wait

Enable your sustainment team with real-time asset visibility, automated workflows, and predictive analytics. Minimize downtime and maximize mission success. Book a DemoDiscover the Game-Changing Benefits AIMS Brings to Your Operation

With AIMS, you get immediate visibility into every asset’s status, streamlined maintenance scheduling, and airtight compliance—all in one cost-effective, user-friendly system. Say goodbye to endless spreadsheets and guesswork, and say hello to a seamless, data-driven future for your fleet.

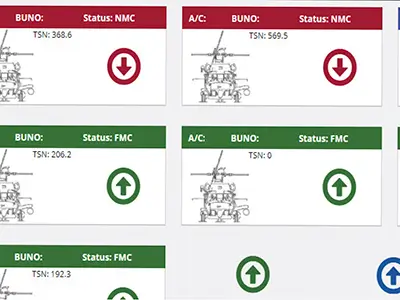

Real-Time Readiness Dashboard

Instantly know your fleet’s mission-capable status and upcoming maintenance requirements.

Compliance You Can Trust

Meets stringent military and commercial standards (FAR regulations, NAMP, SAE-JA-1011, and more).

Cost-Effective Maintenance

Get enterprise-grade capabilities without the baggage of traditional, bloated systems.

FMS/DCS Approved

AIMS is ready to roll for Foreign Military Sales and Direct Commercial Sales, bridging compliance gaps you didn’t even know existed.

Predictive Maintenance (PdM)

Proactively monitor asset health and extend lifecycles to protect your most valuable equipment.

Streamlined, Adaptable Interface

Designed by maintenance pros for maintenance pros, this is intuitive tech that scales with your needs.

AIMS isn’t just another software add-on.

It was forged from the rigorous demands of the U.S. Military and the Naval Aviation Maintenance Program (NAMP). If it can handle strict FAR regulations and the complexities of advanced aircraft systems, imagine how smoothly it will run your organization’s maintenance operations.

No more juggling multiple spreadsheets or outdated modules that aren’t on speaking terms.

Book a Demo Today!

Powerful Capabilities, Mission-Ready Results

AIMS was designed to take the daily grind out of maintenance management—so your team can focus on keeping aircraft mission-ready. With real-time dashboards, automated scheduling, and top-notch compliance, you get boosted efficiency, fewer interruptions, and crystal-clear visibility into every asset.

Bottom line: less stress, fewer bottlenecks, and a more streamlined operation.

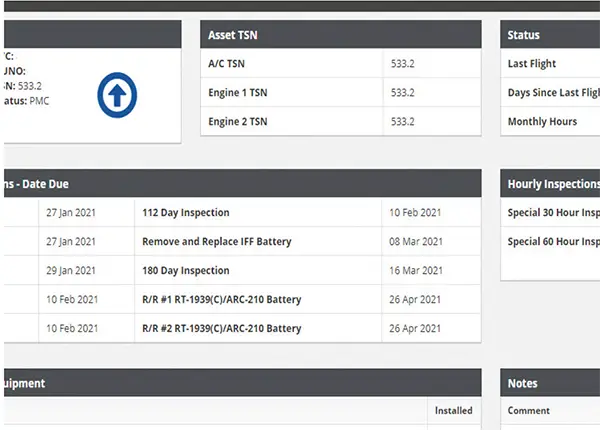

Status Dashboard

“At a glance” visibility of Asset/Fleet status to include mission capable status, next due for key maintenance requirements, mission configuration and operational notes.

Task Developer

Build a maintenance program based on OEM, governing and regulatory authority requirements. Custom requirements can be incorporated to cover unique aircraft configurations or organization-specific operational needs. Changes made to requirements are automatically propagated and visible on any associated asset.

Asset Manager

This module identifies, defines, and documents assets. You can add assets and define attributes such as serial number, location, warranty, and vendor information. The Asset Manager allows you to group assets into physical and functional hierarchies. The interface provides intelligent searches for quick access to various lists and information about your assets.

Maintenance Optimizer

Automated scheduling that optimizes required maintenance, minimizing “downtime,” thereby maximizing asset availability. Manual scheduling adjustments can be made to meet operational needs. Allows for categorical separation of assets to view and manage “like” assets on separate timelines (aircraft, support equipment, calibration equipment, etc.).

Report Center

Contains a list of reports commonly used to facilitate the management of organization assets (e.g., aircraft utilization, near due, life limited component, etc.).

Pilot Log

Captures data associated with aircraft flights & simulator events. Data includes data relevant to pilot & aircrew proficiency, mission types & flight leg information and aircraft usage data.

Work Orders

Real-time visibility of status for all maintenance activities (WOs). Manage every facet of the work order process. Technician assignment & capture of elapsed maintenance time. In-process quality checks. Workflow status changes (awaiting maintenance, in-work, awaiting parts, awaiting other shops, complete, etc.).

Hardware Builder

Hardware Builder defines the physical structure of the assets managed by AIMS, which is used in many other modules. The user can break down the hardware in as much or as little detail as required. For each node in the hardware breakdown, users can define acceptable manufacture and part numbers for application on assets. The system supports the building of both physical and functional hardware trees for detailed analysis using other AIMS modules.

Admin

Establish and manage roles and permissions relative to AIMS personnel accounts. Determines individual access to specific module features.

AIMS has transformed how we manage our fleet. The predictive maintenance feature alone has cut downtime by 30% while keeping us in full regulatory compliance.

Before AIMS, our maintenance scheduling was a nightmare. Now, everything is automated, and our team has real-time visibility into every asset. It’s a game-changer.

Experience AIMS for Yourself—Boost Readiness, Slash Downtime, and Stay Mission-Focused

Still on the fence? Our experts are here to walk you through AIMS’s capabilities and answer any questions. Let’s keep your assets at peak performance—together. Request a demo for a personalized walkthrough of what AIMS can do for you.

FAQs about AIMS

Is AIMS suitable for commercial aviation as well?

Yes, it complies with commercial standards like FAR regulations and more.

Can AIMS integrate with existing ERP or MRO systems?

Absolutely. Our flexible APIs allow for seamless data exchange.

How long does implementation take?

Implementation timeline varies based on fleet size and complexity, but we offer agile deployment options.

Corporate Headquarters

440 Viking Drive, Suite 230

Virginia Beach, VA 23452

Corporate Office

6255 Lake Gray Blvd., Suite 4

Jacksonville, FL 32244

USA Offices

Crystal City, VA

Havelock, NC

Oklahoma City, OK

Patuxent River, MD

San Diego, CA

Get in Touch

904-637-2020

Follow Us

Email Us

"*" indicates required fields