Maintenance time and logistical delays drive high sustainment costs across any maintenance environment. Artificial Intelligence/Machine Learning can automate the analysis in order to optimize maintenance planning, scheduling, and execution.

AIPS was developed with a wide variety of applications in mind, virtually any maintenance environment where the point of performance data is collected.

- Air, Land, and Sea

- Defense

- Transportation

- Energy

- Commercial

Stand-Alone

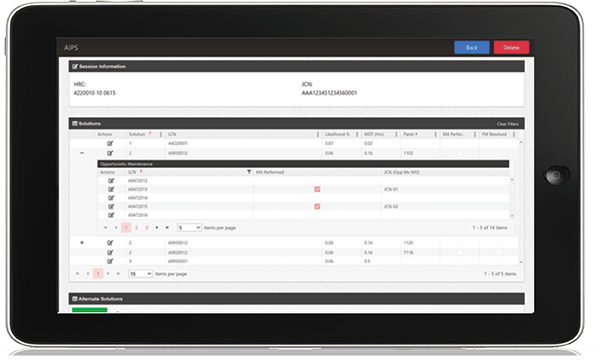

AIPS can be utilized as a Stand-Alone application in support of existing Maintenance Management Systems

Embedded in Existing MMS

AIPS can be embedded within an existing Maintenance Management System

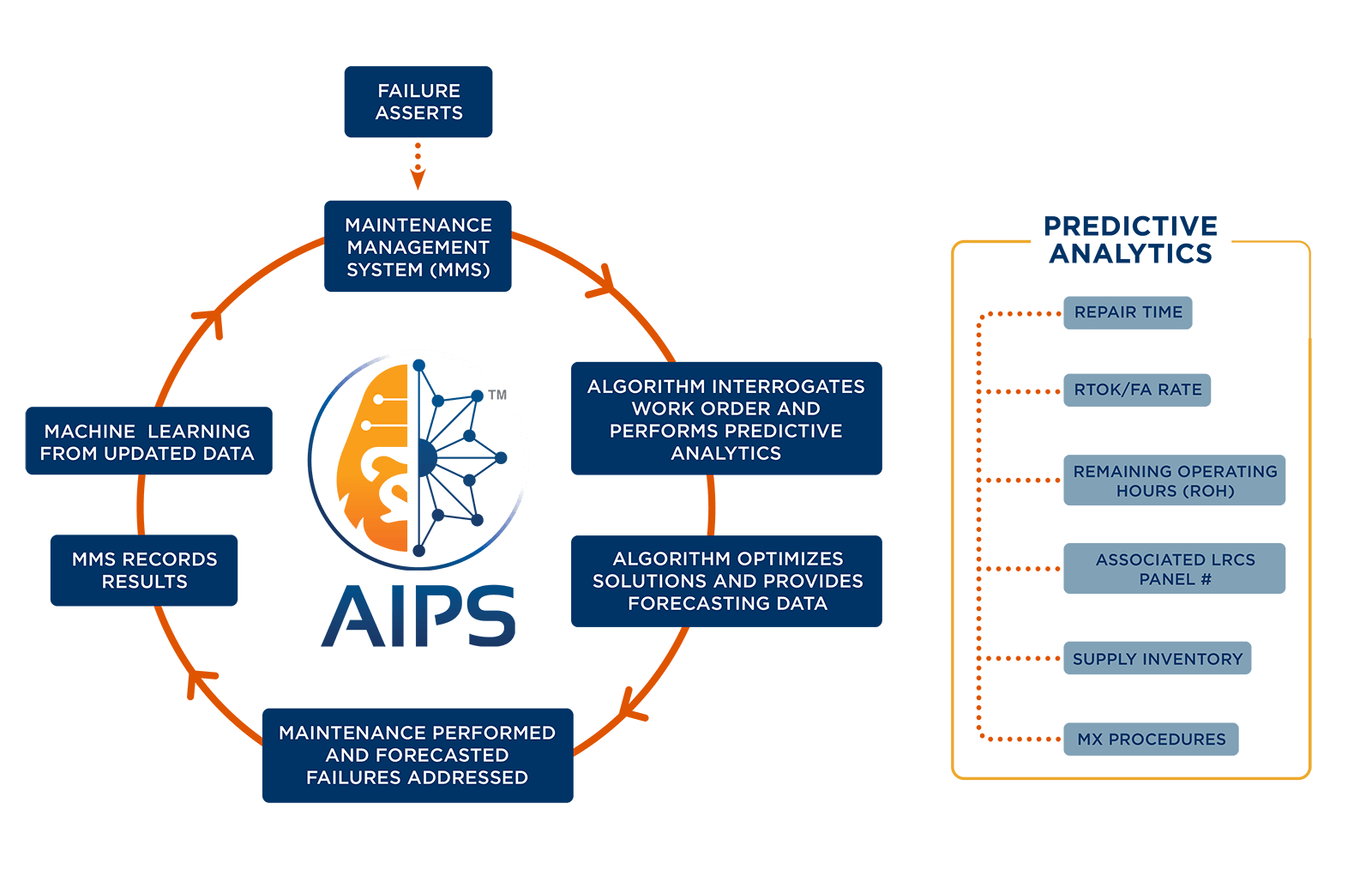

The chart below highlights the AIPS (Artificial Intelligence Prognostic Steering™) system workflow:

AIPS provides this automation and is scalable to diverse data structures and advanced optimization. Available as a stand-alone or integrated within an existing maintenance management system, AIPS provides the most current analysis of the most recent data available.

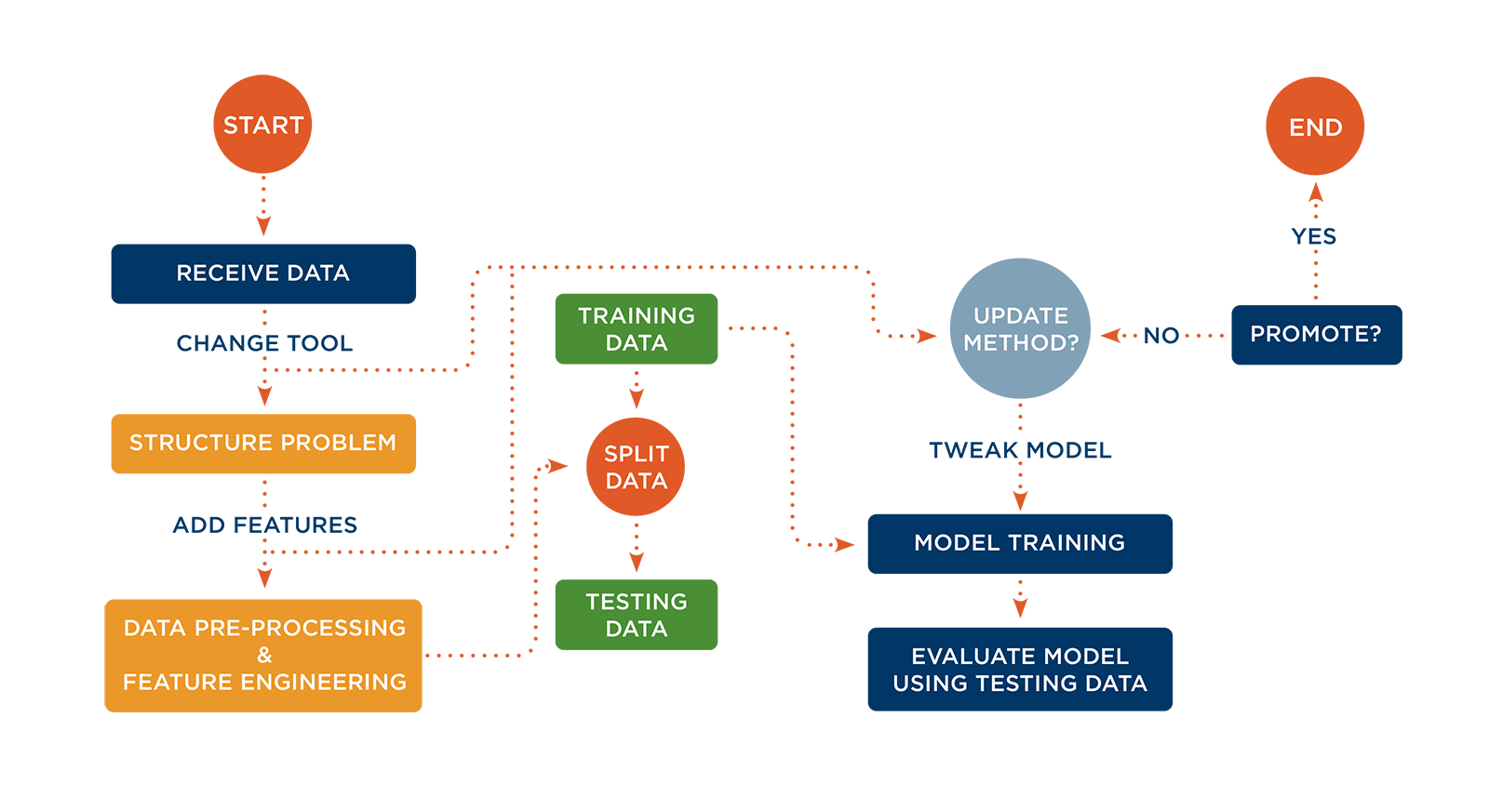

Machine Learning – and AI – are the implementation of statistical models and techniques within an information system architecture that enables iterative:

- Collection of new data

- Machine-driven adjustment of the model parameters to improve performance

In similar fashion to most engineering work, developing a machine learning algorithm involves:

- Structuring the problem in a way that it can be addressed by one (or a combination of) the tools available. Every needs to be turned into one of a finite set of structures so it can be processed using an existing tool – it needs to be structured into either a nail, a screw, a bolt, or a fastener.

- Processing the raw data to clean, extract, and identify the relevant features.

- Feeding the subset of the processed data into a mathematical model.

- Adjusting the model parameters to optimize its performance against a separate subset of test data.

- Developing an information system that allows for the periodic retraining of the model.

The chart below highlights the Machine Learning workflow:

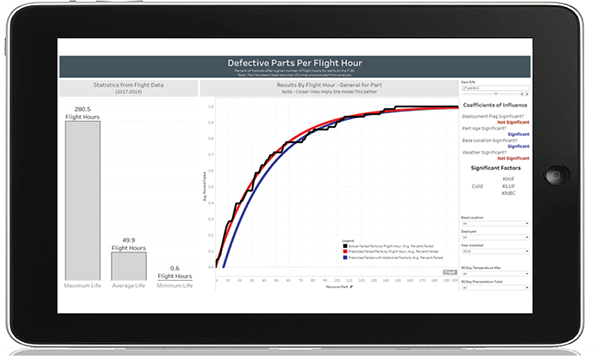

AIPS testing within the Department of Defense

Improved 1st attempt failure resolution by 300%

Reduced solution sets size by an average of 40%

Reduced 54% of solution sets to a single solution

Increased False Alarm identification by 72%

Decreased Maintenance due to False Alarms by 70%

Decreased repair times by an average of 15.4%

AIPS Solutions – what we can achieve

Increase Readiness rates

Forecast Failures by component, time and location

Identify False Alarms (FA)

Optimize Maintenance Procedures

Reduce Maintenance Costs

Reduce Maintenance Times

Reduce Panel Intrusions

Reduce Unnecessary Maintenance due to FA

Reduce Unnecessary Maintenance due to FA

Improve Root Cause Analysis

Next-Gen features to include:

Account for weather in failure prediction

Account for Operations in failure prediction

Adjudicate Maintenance Data

Feed Supply for optimized provisioning

Account for Operator/Maintainer in failure forecasting

Feed Mission Planning/Forecasting

BOOK A DEMO

Learn how Artificial Intelligence Prognostic Steering™ with AIPS will benefit your business. We provide a customized tour and can answer all your questions.

AIPS GUIDE

Download our Artificial Intelligence Prognostic Steering™ with AIPS brochure for a more in-depth guide to available solutions.

Corporate Headquarters

440 Viking Drive, Suite 230

Virginia Beach, VA 23452

Corporate Office

6255 Lake Gray Blvd., Suite 4

Jacksonville, FL 32244

USA Offices

Crystal City, VA

Havelock, NC

Oklahoma City, OK

Patuxent River, MD

San Diego, CA

Get in Touch

904-637-2020

Follow Us

Email Us

"*" indicates required fields