RCM Analysis Services, Software, and Training

ASI provides Reliability-Centered Maintenance (RCM) analysis services, facilitation, training, and RCM analysis software to assist physical asset owners in implementing and improving cost-effective maintenance programs using a logical and comprehensive SAE JA1011 compliant RCM process. Our RCM process is based on the process used by the US Naval Air Systems Command as described in NAVAIR 00-25-403. The US Navy has been a leader in RCM analysis since the

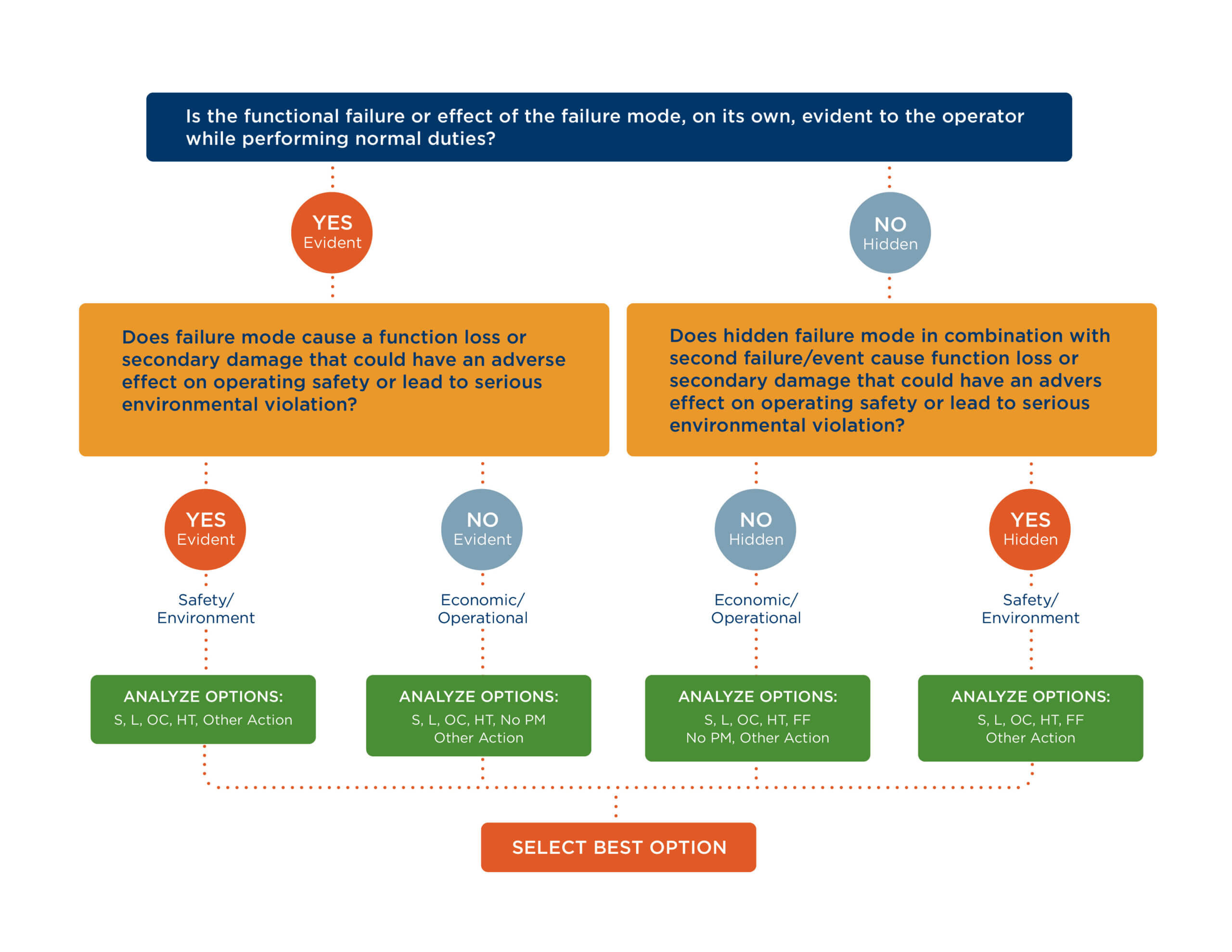

RCM analysis is an analytical process that determines appropriate preventive maintenance requirements and other failure mitigation strategies for physical assets. RCM analysis is based on the concept of identifying the optimum failure mitigation strategy for each failure mode of an asset.

RCM Logic Process Overview

RCM applies to any industry that requires reliable, cost-effective performance from their assets. Applicable industries include, but are not limited to, Manufacturing, Pharmaceutical, Food Processing, Chemical Processing, Mining, Facilities, Weapon Systems, Aerospace, Agriculture, Alternative Energy, Energy Distribution, and Power Generation.

History of RCM

RCM concepts were developed from research in the 1960s by the Federal Aviation Administration (FAA) and the commercial aviation industry while looking for ways reduce the cost of maintenance that was based on extensive periodic overhauls of equipment.

Interesting findings from this research included:

- Failure of components did not correlate to age in many cases

- Periodic overhaul did not improve system reliability and often decreased it (infant mortality)

- The concept of potential failures and condition-based maintenance (only taking corrective action when a potential failure was discovered) was introduced.

- Maintenance Steering Group (MSG) logic was developed as the first analytical means to develop preventive maintenance requirements based on these findings

In 1978, United Airlines was asked by the US Department of Defense to develop a process based on the MSG logic for its systems and RCM was born. Over the years many variations and refinements of the process have been developed for use in a myriad of industries.

Today the most widely accepted forms of RCM follow the Society of Automotive Engineers (SAE) Standard SAE JA1011, Evaluation Criteria for Reliability Centered Maintenance (RCM) Processes with a minimum criteria to achieve the RCM standard. SAE JA1011, available from http://www.sae.org

Capabilities

Our internationally recognized staff includes individuals who participated in the development of the Society of Automotive Engineers (SAE) JA1011 and SAE JA1012 standards, and the NAVAIR 00-25-403 RCM Manual. Our team also includes over twenty NAVAIR certified Level II and III analysts, certified SMEs, and instructors. We have completed dozens of successful RCM projects on a broad range of assets including military aircraft and weapon systems, vehicle fleets, hospital facilities, data centers, manufacturing equipment, and mining equipment. Our staff has been supporting RCM projects for nearly 30 years. Our experience across multiple industries and our flexible approach to RCM ensures the highest possible return on investment.

What Makes Us Different?

Non-Proprietary SAE JA1011 based RCM process, no licensing or certifications required.

Analysis and implementation approach adapted to your organization needs (facilitation, analysis support, mentoring, and training).

Experience with a broad range of industries including aviation, vehicles, defense, mining, manufacturing, MRO, data centers, hospitals, power generation, and more.

Industry Leadership: Our internationally recognized experts participated in the development of the SAE RCM Standards JA1011 and JA1012. Click Here

Expertise in related fields such as reliability modeling, simulation, statistical analysis, fracture mechanics, Predictive Maintenance, Condition Based Maintenance, and Non-Destructive Inspection/Testing (NDI/T).

Features & Benefits

Develop a comprehensive RCM based failure management program for your assets that minimizes cost and maximizes availability while ensuring safety.

Identify optimal failure management strategies for each piece of equipment and each significant failure mode.

Identify and address potential failure conditions using the latest in predictive and condition monitoring technologies.

Use criticality analysis to prioritize analysis efforts and ensure maximum return on investment.

Provide inputs into maintenance planning efforts by identifying maintenance task requirements and frequency of occurrence.

Improve maintenance troubleshooting capability through the structured documentation of failure symptoms and causes.

Establish a document and data repository that provides easy access for updating your maintenance program as new information becomes available.

Minimize expensive unscheduled/reactive maintenance requirements.

Enjoy the confidence of a fully SAE JA1011 and NAVAIR 00-25-403 compliant process.

Use our state-of-the-art web-based RCM Software or any others that support a JA1011 compliant process.

Support tailored to your organization’s needs, including RCM Analysis training courses available at your site or ours. Training provides both basic and advanced classes to assist you in setting up or enhancing your RCM program.

Case Studies

Major US Airline Data Center

We implemented an intensive and comprehensive maintenance program for a large data center that included complete equipment evaluation and analysis that resulted in an RCM justified preventive maintenance program utilizing the latest in predictive maintenance technologies and evaluation. This analysis of a new green field project successfully developed an optimized PM plan for critical electrical equipment that included complete Maintenance Task Analysis (job plans), a PdM Plan, and Lock Out-Tag Out procedures. An expected annual reduction of approximately $160,000.00 should be realized from original PM program costs with the full implementation of the optimized Preventive and Predictive Maintenance program.

Contact Us

Learn how we can help you optimize the support of your fleets and physical assets.

Corporate Headquarters

440 Viking Drive, Suite 230

Virginia Beach, VA 23452

Corporate Office

6255 Lake Gray Blvd., Suite 4

Jacksonville, FL 32244

USA Offices

Crystal City, VA

Havelock, NC

Oklahoma City, OK

Patuxent River, MD

San Diego, CA

Get in Touch

904-637-2020

Follow Us

Email Us

"*" indicates required fields