Supportability Analysis Services

ASI is an internationally recognized leader in the Supportability field, developing innovative tools and processes to support asset managers across the globe. We provide supportability solutions and services in all phases of the asset life-cycle.

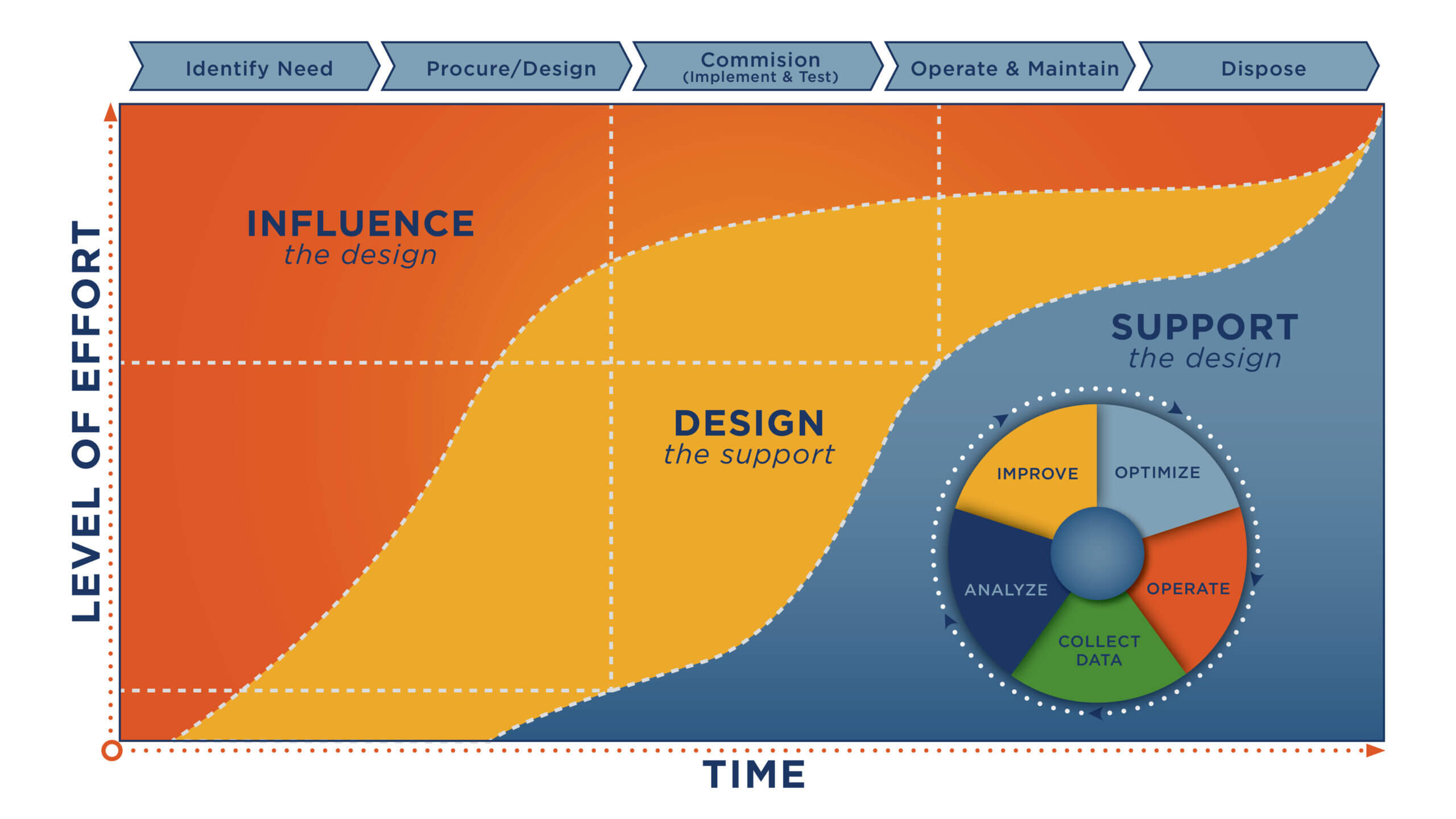

Supportability analysis is a systematic approach used throughout a product’s lifecycle to ensure assets and their support systems effectively achieve desired performance while minimizing costs and maximizing operational availability. It assesses the system’s design alongside associated support resources, such as spare parts, tools, and training, to proactively identify potential issues and optimize sustainment strategies early in development. Central to supportability analysis is Supportability Optimization, which maximizes the effectiveness of support systems through robust analytics—rather than guesswork—to achieve optimal asset performance at the lowest possible cost. Ultimately, effective supportability analysis helps answer critical questions such as, “Where will my next dollar deliver the greatest impact on asset performance?”

Supportability is:

- Influenced by both the design of the asset and the design of the support system

- Impacted by the operating environment

- A function of Reliability, Availability, Cost, and Safety

Supportability, like reliability and maintainability, is both a measure of effectiveness and a related discipline that endeavors to maximize it. Supportability analysis in the Government and Defense sectors is defined in several prescriptive standards such as the Society of Automotive Engineers (SAE) SAE-GEIA-STD-0007 (Logistics Product Data),

Supportability over the Asset Life-Cycle

Capabilities

Condition-Based Maintenance & Prognostics Systems development

Failure Modes Effects and Criticality Analysis (FMECA)

Level/Location of Repair Analysis (LORA)

Lifecycle Cost Analysis

Maintenance Planning

Maintenance Task Analysis (Maintenance Job Plans)

Maintenance Concept Development

Maintenance Management System Configuration & Integration

Reliability-Centered Maintenance (RCM) Analysis

Reliability Block Diagrams (RBD)

Reliability Modeling and Analysis

Root Cause Analysis (RCA)

Spare Parts Provisioning Analysis

Support Equipment Requirements Development

Supportability Analysis (formerly Logistics Support Analysis or LSA)

Supportability Modeling and Simulation

Supportability Optimization

Support Concept Development

Technical Data Development

Training Systems Development

What Makes Us Different?

Diverse Experience

We have performed supportability analysis on projects ranging from military aircraft, military and commercial ground vehicles, work boats, data centers, hospitals, mining equipment, manufacturing equipment, and more.

Industry Leadership

Our internationally recognized experts serve as members of key technical committees such as the Society of Automotive Engineers (SAE) Life-Cycle Logistics Support Committee responsible for SAE-GEIA-STD-0007 (Logistics Product Data) and SAE-TA-0017 (Product Support Analysis).

Capable Team

We have a large team of analysts, logisticians, engineers, and IT professionals with a diverse range of technical skills and experience that are ready and able to support any size project.

State-of-the-Art Tools & Processes

We have developed a comprehensive integrated suite of supportability tools that incorporate advanced analytical models and techniques.

Features and Benefits

Obtain desired performance from your physical assets and fleets at minimum life-cycle cost.

Increase Equipment uptime and reliability.

Understand which factors have the most influence on system performance and how changes to those factors can improve performance.

We provide support tailored to your organization’s individual needs from training to defined analysis projects to long-term on-site support.

Contact Us

Learn how we can help you optimize the support of your fleets and physical assets.

Corporate Headquarters

440 Viking Drive, Suite 230

Virginia Beach, VA 23452

Corporate Office

6255 Lake Gray Blvd., Suite 4

Jacksonville, FL 32244

USA Offices

Crystal City, VA

Havelock, NC

Oklahoma City, OK

Patuxent River, MD

San Diego, CA

Get in Touch

904-637-2020

Follow Us

Email Us

"*" indicates required fields