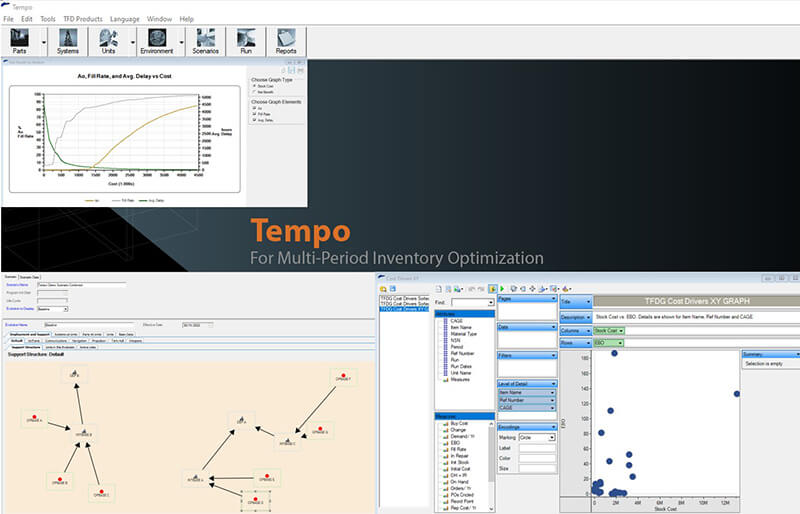

Tempo

The Next GenerationInventory Optimization ToolAre You Still

Steady-State Planning?

Is your operational usage or fleet disposition likely to change over time through fleet expansion, re-basing, re-role or run-down?

Is it probable that your equipment design will change over time because of obsolescence, modifications, upgrades, or reliability improvement programmes?

Have you considered the need to minimize wasted investment in stock with a short useable life?

Do you struggle with making logistics decisions affected by: fleet build-up and run-down, obsolescence and technology refresh, the impact of reliability improvements, planning for ageing systems, long lead-time versus short lead-time buys, PBL incentive schemes with complex metrics, or future program changes such as Ao targets, operating hours and basing?

Inventory planning is a complex discipline demanding the most sophisticated algorithms to ensure that the right inventory is acquired and located at the right place. Until now, all spares optimization tools have assumed long-term, steady-state scenarios, which remain unchanged forever. In the real world, the situation always changes as basing, activity levels, support arrangements and system configuration evolve.

Trying to accommodate such change using steady-state analysis tools can only be achieved by chaining together a sequence of runs, but each run is unaware of subsequent changes and optimizes a permanent situation. This repetitive approach is laborious, time-consuming, prone to error and will invariably provide a sub-optimal solution. Nor does simulation offer a solution, since it is limited to the evaluation of solutions already determined by analysis. Tempo changes the game for spares optimization by incorporating the economic impact of time on inventory decisions.

Evolved from the proven VMetric optimization engine, Tempo takes account of both predictable changes in hardware and foreseeable changes in operating and support scenarios. Tempo is the first and only tool for developing optimum spares scales to meet fleet availability targets where: operational usage or fleet disposition changes over time through fleet expansion. It can also accommodate re-basing, re-role or run-down; equipment design changes over time because of obsolescence, modifications, upgrades, or reliability improvement programmes; and support arrangements changing over time as maintenance, repair policies, contractors, performance and price evolve.

Tempo

Brings a time dimension to spares optimization by explicitly handling inevitable changes in scenario

Avoids the errors implicit in steady-state models, including over-stocking of life-limited and long-lead time parts

Maximizes return on investment and avoids waste from market-driven obsolescence by minimizing wasted investment in stock with a short useable life

Optimizes procurement timing to match fleet build-up, re-basing and run-down for lowest cost

Deals explicitly with time, eliminating the drudgery of hand-made multi-period calculations

Tempo – The Next Generation Inventory Optimization Tool

Further information about TFD tools, techniques, and methodology can be found on our downloads page.