Landscape Maintenance Software

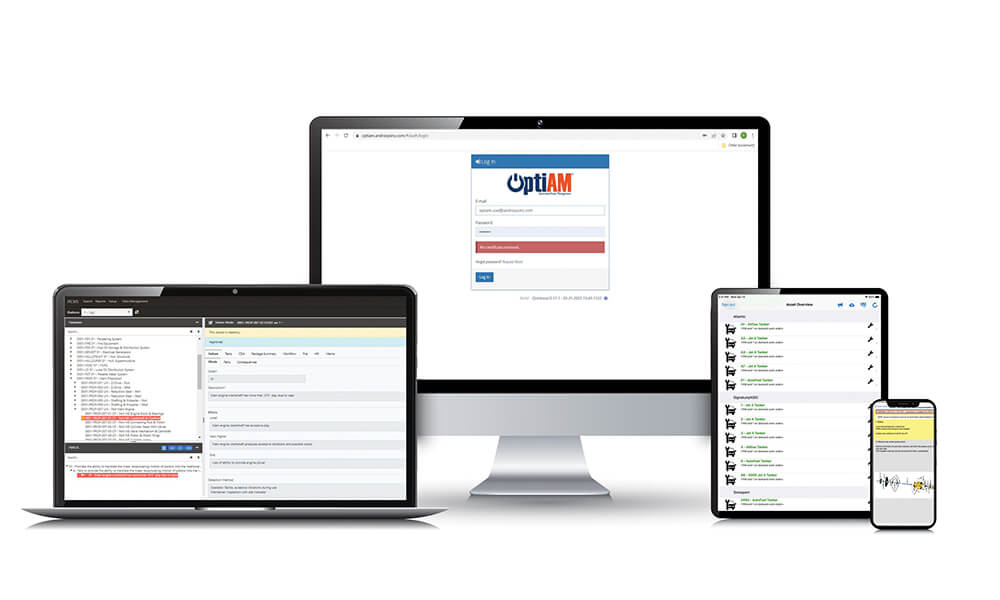

OptiAM® is designed to optimize the performance of your landscsaping equipment to keep your business running. Schedule a Call to Learn MoreOptiAM® is a powerful EAM solution designed to streamline maintenance, maximize asset performance, and reduce downtime for landscape maintenance companies.

OptiAM® is an Enterprise Asset Management Software/(EAM) system designed to be easy to use and quickly implemented while leveraging powerful predictive analytics and mobile technology.

Originally developed for the exacting standards of the U.S. Military by experienced maintenance personnel, OptiAM® applies to a wide range of asset types in any industry environment.

Benefits for Your Landscape Equipment Management

Reduced implementation and training costs

Highly competitive licensing costs

Designed to support seamless integration with existing applications and databases

Ability to customize interfaces and processes shortens learning curves

Incorporates latest technology including mobile, Radio Frequency Identification (RFID) and Predictive Maintenances

Simple and intuitive interface

Latest web-based technology ensures maximum reliability and security

Data is translated into actionable knowledge, enabling continuous improvement.

Built on Analytics

OptiAM® delivers results far beyond those of other enterprise asset management systems because it is built on the analytical power of Reliability Centered Maintenance (RCM) and Supportability Analysis, along with advanced optimization techniques. With these advanced tools and technologies at your fingertips, you can develop predictive maintenance and support programs that continuously improve over time.

Asset Management

ISO-55000 defines a physical asset as equipment, inventory, or property owned by a person or company with actual or potential value to that person or organization. Asset management is the coordinated activities of an organization to realize value from its assets. Asset management involves balancing those assets’ costs, risks, opportunities, and benefits. Optimization is maximizing or minimizing a desired objective, such as uptime or cost. Optimization also considers known constraints, such as available manpower or maintenance facilities.

Get Insight into Asset Performance with Real-Time Status Updates from your Landscape Maintenance Software

OptiAM® is a module based software which can be tailored

to your needs. OptiAM® modules include:

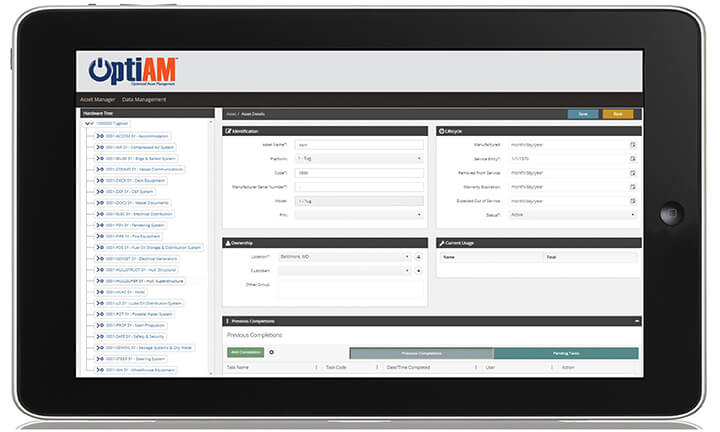

Asset Manager

This module identifies, defines, and documents assets. You can add assets and define attributes such as serial number, location, warranty, and vendor information. The Asset Manager allows you to group assets into physical and functional hierarchies and identify assets via QR code or RFID tags.

The interface provides the ability to quickly move an asset from one location to another or from one user/team to another user/team.

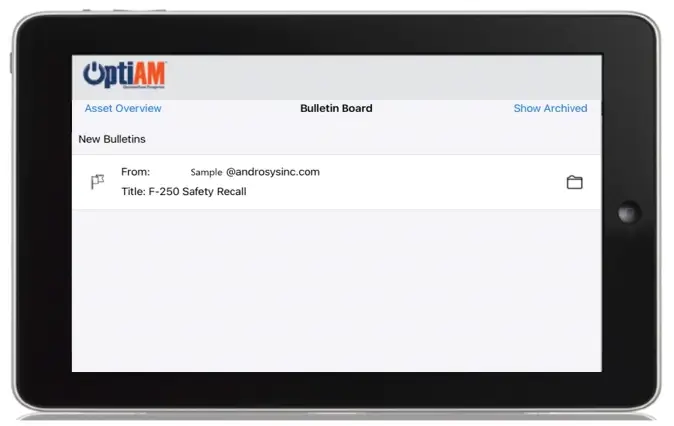

Bulletin Board

Send safety-related messages to specific users, user roles, or user permissions and locations. Users are required to read and acknowledge receipt of the bulletin, and an electronic record is stored for historical purposes.

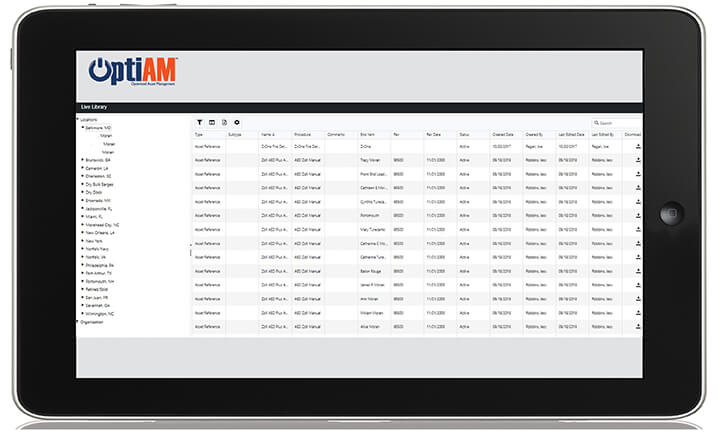

Live Library

With the Live Library, all available maintenance, operating procedures, and resource information are at the fingertips of any user in any location. The Live Library stores, associates, and classifies technical data associated with individual assets, providing an intuitive, searchable interface for easy access. The Live Library also allows users to add notes and comments to documents and utilize a print function to promote knowledge sharing.

Checkout Logs

Create custom equipment checkout logs and quickly assign vehicles or equipment to a specific individual or team. Take pictures of the equipment from our mobile app at the time of checkout and record the equipment condition when it is assigned and returned to your facility.

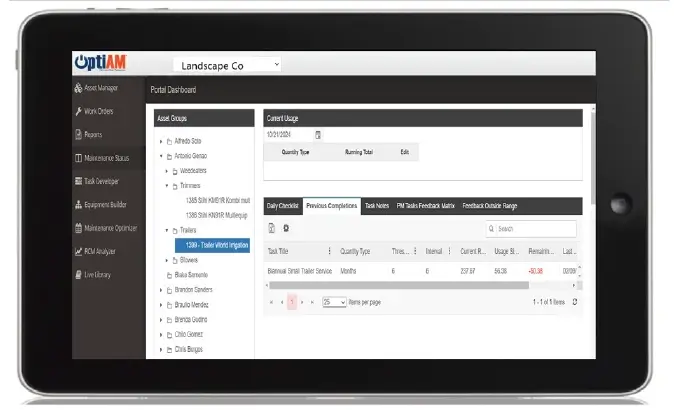

Dashboards

Quickly view all your vehicles and equipment and see what individual user or team has custody of the equipment. Check current miles and hours on your equipment, upcoming PM schedule, and any alerts that your equipment may require maintenance.

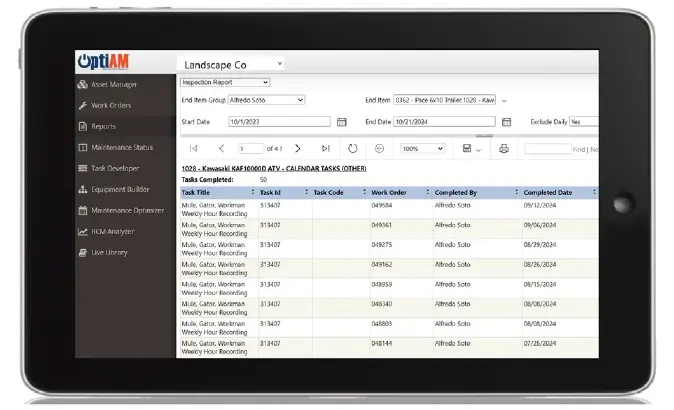

Reporting

Quickly access maintenance records and service history for any vehicle or piece of equipment. Reports show the date of planned or corrective maintenance, who performed the maintenance, what was done, and any readings or notes the technician recorded during the maintenance procedures.

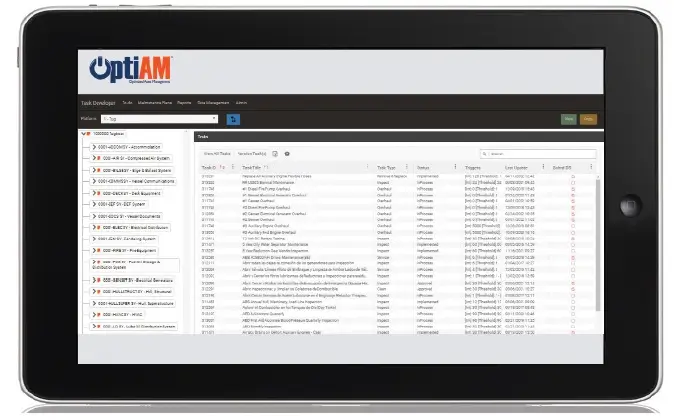

Task Developer

Develop the procedures and identify the resources needed to support your assets. Task Developer identifies resources needed to perform preventative and corrective maintenance tasks and groups these tasks into maintenance packages. The Task Developer can also generate maintenance manuals, standard operating procedures (SOP), and emergency operating procedures (EOP).

Revisions can be tracked, and releases controlled. Task Developer also creates automated checklists for use with the OptiAM® Mobile applications.

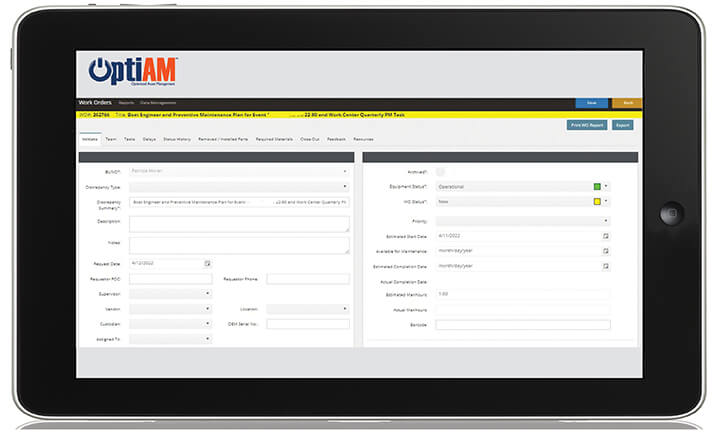

Work Order Manager

Optimize your maintenance schedule based on individual asset usage and environment to minimize downtime or cost. The Maintenance Optimizer provides a full-featured work order management system to schedule, manage, execute, and document maintenance workload. It can also schedule actions such as contract or warranty renewals and planned upgrades and set alert triggers to generate automated work orders based on inputs from inspections, PdM, or equipment monitoring systems. The Maintenance Optimizer provides near real-time equipment status to other modules in OptiAM®.

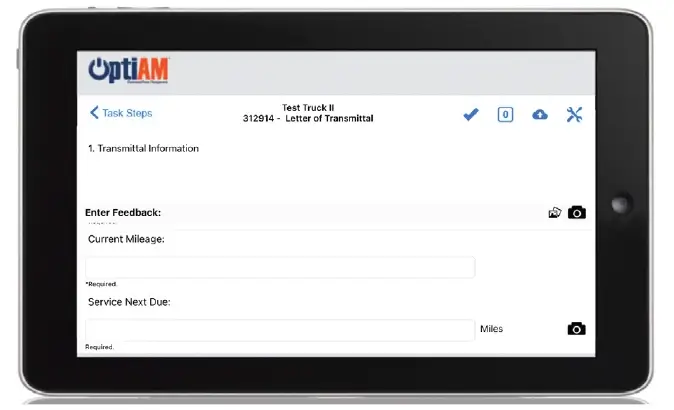

OptiAM® and OptiAM® Mobile Applications

Improve maintenance accuracy and efficiency by accessing technical data and documenting work at the point of performance.

These applications allow you to operate offline or online via cellular or Wi-Fi. The applications manage and synchronize work orders at the equipment, giving you access to searchable technical data and attached multimedia such as instructional videos. You can scan parts for work orders and inventory control using optical codes or RFID. OptiAM® and OptiAM® Mobile use text and media capture to record results and capture electronic checklist results.

System requirements

Developed using the latest rich Internet application technology and standard data formats, this solution’s integrated data environment delivers an intuitive and consistent user experience across all major operating systems. It is available as an installed or software as a service (SaaS) system. Please refer to the systems requirements below:

SaaS

OptiAM® is also offered as Software as a Service (SaaS). The many advantages of the SaaS solution include easier setup, lower initial cost, painless upgrades, and no system administration. The hosted solution provides data security, redundancy, and backup. Servers are hosted in a professionally managed hosting facility providing redundant backup power, fire suppression, redundant tier 1 Internet access, and biometric-controlled physical access. We manage all software licensing for you.

INSTALLED

An installed option is offered to host OptiAM® within your company’s IT infrastructure. The system can be installed on a shared or dedicated server, either physical or virtual. The operating system must be Microsoft Windows Server 2016 or later, including IIS v10 or later and .NET Framework 4 or later. OptiAM® also requires Microsoft SQL Server 2016 or later. If the mobile components are to include an additional license for Adobe Cold Fusion 10 or later, it must be provided. All backups and restoration would be the responsibility of your company’s IT department.

Book a Demo

Learn how OptiAM® will benefit your business. We provide a customized tour and answer your questions.

OptiAM® Guide

Download our OptiAM® Landscape Brochure for a more in-depth guide to our Enterprise Asset Management solution.

What our OptiAM® clients are saying…

Corporate Headquarters

440 Viking Drive, Suite 230

Virginia Beach, VA 23452

Corporate Office

6255 Lake Gray Blvd., Suite 4

Jacksonville, FL 32244

USA Offices

Crystal City, VA

Havelock, NC

Oklahoma City, OK

Patuxent River, MD

San Diego, CA

Get in Touch

904-637-2020

Follow Us

Email Us

"*" indicates required fields