Maintenance affects equipment reliability, safety, and cost. A successful strategy doesn’t wait for problems—it prevents them. Transitioning from reactive fixes to proactive planning enables organizations to extend asset life, minimize downtime, and enhance performance.

What Is Reactive Maintenance?

Reactive maintenance is the practice of repairing equipment after it breaks. It’s often known as “run-to-failure” maintenance. This approach appears convenient and cost-effective at first glance. Teams wait for failure, then respond.

But reactive strategies create problems over time. Unexpected failures can lead to operational delays, higher emergency repair costs, and safety concerns.

Risks of a Reactive Approach

Sticking with reactive maintenance can be expensive and disruptive:

- Downtime: Unplanned failures slow down operations.

- High Costs: Emergency repairs cost more than planned ones.

- Safety Hazards: Sudden failures increase the risk of accidents.

- Shortened Equipment Life: Allowing machines to run to failure can damage critical components.

While this approach may work for low-impact assets, it’s not suitable for critical operations or long-term planning.

What Is Proactive Maintenance?

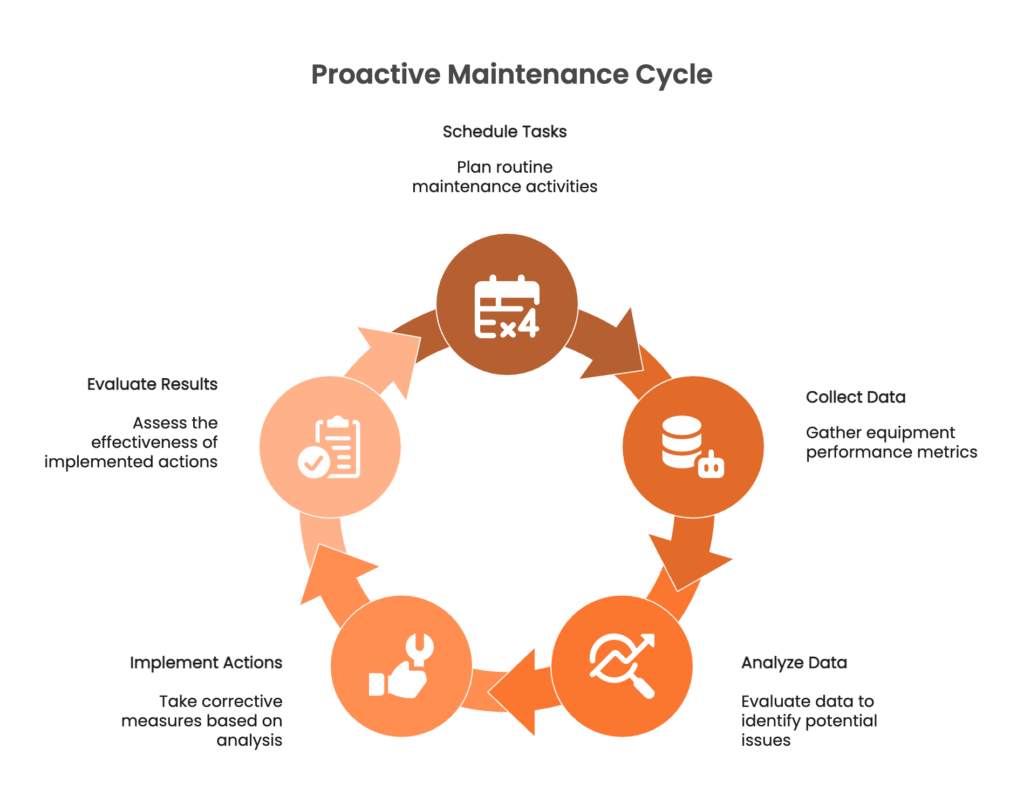

Proactive maintenance prevents failures from occurring. It relies on scheduled tasks, equipment data, and analysis. This strategy reduces surprise breakdowns and extends the life of assets.

Organizations utilize tools such as computerized maintenance management software (CMMS) and enterprise asset management software (EAM), like OptiAM, to support this approach.

Proactive Maintenance Types

Several proactive methods help reduce failure risk:

1. Preventive Maintenance (PM)

This involves routine tasks at set intervals, such as inspections and part replacements. It is based on time or usage—for example, every six months or every 5,000 cycles.

Preventive maintenance reduces wear but can result in unnecessary service if not based on the actual condition of the equipment.

2. Predictive Maintenance

Predictive maintenance utilizes sensor data to monitor equipment in real-time. Tools such as predictive maintenance software track key metrics, including temperature, vibration, and pressure. When values fall outside safe ranges, action can be taken to prevent failure from occurring.

This reduces wasted labor and increases efficiency.

3. Reliability Centered Maintenance (RCM)

RCM (Reliability-Centered Maintenance) is a structured method that analyzes asset functions and the effects of failure. It results in a customized maintenance plan tailored to risk, cost, and safety considerations.

To apply this method, many professionals pursue RCM training or enroll in reliability-centered maintenance training. The goal is to make better decisions for critical equipment.

Why Shift to Proactive Maintenance?

The benefits of proactive maintenance are clear:

- Lower Costs: Planned maintenance avoids emergency fees.

- Higher Equipment Uptime: Fewer unplanned failures lead to improved productivity.

- Improved Safety: Well-maintained machines are safer to use.

- Longer Asset Lifespan: Consistent care delays major repairs and replacements.

- Better Resource Planning: Maintenance teams can manage time and parts more effectively.

Proactive strategies are easier to manage using tools like the best CMMS software or EAM software.

Building a Proactive Maintenance Strategy

Here are the essential steps:

1. Evaluate Your Current Maintenance Approach

Review how much of your current work is reactive versus planned. Look at breakdown history, asset performance, and maintenance costs.

2. Identify High-Impact Equipment

Focus on assets critical to operations. Consider safety implications, repair costs, and how failures affect output.

3. Use Maintenance Management Tools

Adopt a CMMS, maintenance management software or enterprise asset management Software package. These systems track equipment data, automate scheduling, and support reporting.

4. Plan Routine Tasks

Create schedules for inspections, part replacements, and cleaning. This forms the base of a preventive maintenance program.

5. Train Your Team

Ensure your staff understands how to utilize new tools and processes effectively. Training improves consistency and performance.

6. Measure and Adjust

Track progress over time. Use system data to monitor asset performance and maintenance efficiency. Adjust your plan as needed to improve results.

Your Path to Long-Term Maintenance Success

Reactive maintenance leads to more downtime, safety issues, and higher costs. Shifting to a proactive strategy creates long-term savings and improves equipment performance.

Andromeda Systems Incorporated (ASI) provides tools and services to support this shift. Whether you’re exploring RCM training, implementing reliability-centered maintenance software, or choosing the best CMMS software for your needs, ASI helps asset managers and program leaders improve reliability and control costs.

Ready to build a smarter maintenance strategy? Schedule a discovery call with ASI and take the first step to long-term operational success.