If you manage a fleet of service vehicles, heavy equipment, or large-scale infrastructure, you know how fast things fall apart without the right system in place. Missed preventive maintenance, scattered work orders, and outdated records can lead to downtime, rising costs, and safety concerns.

For organizations such as transit authorities, utilities, defense contractors, and manufacturers, selecting the proper Enterprise Asset Management (EAM) software isn’t optional—it’s essential.

You need a system that:

- Keeps maintenance on schedule

- Gives you real-time insight across all locations

- Tracks critical data at the point of performance

- Helps you plan smarter and avoid costly failures

- Supports your team’s structure, roles, and workflows

In this guide, we’ll break down what EAM software does, the features that solve your daily headaches, and how to choose a solution like OptiAM® that fits your assets, your team, and your goals.

What Is EAM Software?

OptiAM® Enterprise Asset Management (EAM) software enables you to manage the entire lifecycle of your physical assets. It tracks the location of assets, their condition, when they require service, and their performance.

Companies utilize EAM tools to minimize downtime, prolong equipment lifespan, and effectively manage maintenance schedules. If your operations rely on fleets, aircraft, facilities, or large-scale equipment, EAM software gives you the visibility and control you need.

Key Features to Look For in EAM Software

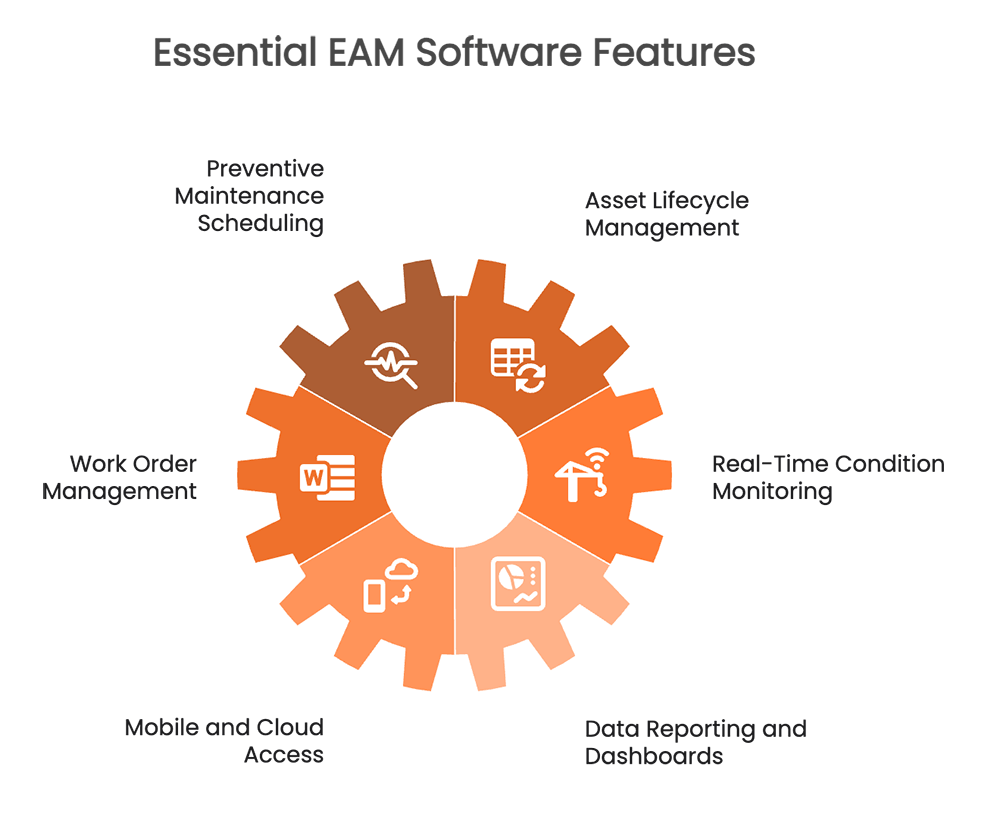

When comparing options, focus on these essential features:

- Preventive Maintenance Scheduling: Automate service plans to reduce unplanned failures.

- Asset Lifecycle Management: Track every phase, from acquisition to disposal.

- Work Order Management: Assign, monitor, and close out jobs in a structured way.

- Real-Time Condition Monitoring: Utilize sensors and diagnostics to monitor asset health in real-time.

- Mobile and Cloud Access: Keep your teams connected in the field or on the move.

- Data Reporting and Dashboards: Gain clear insights into performance, cost, and reliability.

Each feature adds value by helping you reduce waste, improve uptime, and make informed choices.

Questions to Ask Before You Choose EAM Software

Not every company needs the same solution. Ask these questions to define your needs:

- What types of assets do we manage?

- Do we need to track work in the field or across multiple locations?

- What compliance or reporting requirements must we meet?

- Who will use the software, and how many licenses do we need?

- What level of support and training does our team require?

Answers to these questions will help you narrow the list of suitable systems.

How the Right EAM Software Supports Your Goals

A well-matched EAM system does more than log data. It delivers value by:

- Minimizing downtime

- Reducing repair costs

- Improving technician efficiency

- Tracking asset health over time

- Supporting smarter capital planning

EAM software gives decision-makers clear information to act on. This saves time and money while helping teams work more efficiently

How to Compare EAM Software Vendors

Not all EAM systems are built the same. Here’s what to review when comparing providers:

- Is the system cloud-based, on-premise, or both?

- Does it support mobile devices for field use?

- What integrations are available with existing systems?

- How are security, backups, and data access handled?

- What’s included in the total cost (licenses, support, updates)?

These details impact how quickly your team can adopt the software and the long-term value you derive.

Why Companies Choose OptiAM®

Andromeda Systems Incorporated (ASI) provides OptiAM®, an advanced EAM software platform trusted across military, aviation, and industrial environments. OptiAM® is designed to improve performance, reliability, and cost control.

It supports decision-makers with real-time asset data, simple dashboards, and mobile access for teams in the field. OptiAM® is also scalable, secure, and compliant with Department of Defense requirements, making it ideal for high-demand operations.

Final Checklist: Is This the Right Fit?

Before you decide, run through this checklist:

- Do you need mobile-friendly access?

- Will you track preventive and predictive maintenance?

- Does the system match your asset types and structure?

- Can it scale with your operations?

- Is training and support included?

If you’ve checked most or all of these boxes, you’re ready to move forward.

The right enterprise asset management software will save you time, reduce unplanned downtime, and extend the life of your equipment. With the right features and the right partner, your team can make smarter decisions every day.

Want to improve how you manage your assets and fleets at the lowest possible cost?

Schedule a discovery call to learn how their tools and services help asset-intensive organizations run smarter, more reliable operations, saving money and increasing performance across the full asset lifecycle.